Top Strategies to Prevent Inventory Shrinkage

Analyze the size of the loss to place them in the right account in the books. He world market losses billions of dollars in inventory shrinkage each year. Managing inventory shrinkage is important to reduce inventory costs and improve margins. Finally, when you spot inventory shrinkage, document it immediately. Be thorough in noting what has gone missing or been damaged and why. The sooner you identify a problem, the faster it can be corrected.

Retail market showing resilience despite headwinds: Morguard’s Keith Reading

If you haven’t already done so, make sure to create clear guidelines for the receiving process. Implementing redundancies in the receiving process will help create so-called “safety nets” in case one check fails to catch a mistake. Conduct comprehensive background checks before doing business with them and establish clear receiving protocols. Consider investing in anti-theft systems like Electronic Article Surveillance (EAS) and Radio Frequency Identification (RFID) tags. Now subtract total inventory in the stock from inventory mentioned in the books.

- Streamline your inventory management process further by assigning each product a unique identifier, such as SKUs, barcodes, serial numbers, or GTINs.

- Implementing stringent quality controls can reduce the financial impact of damaged goods on inventory shrink.

- You can calculate inventory as a value, a unit figure, or a percentage.

Experience the simplest inventory management software.

- This shrinkage formula lays the groundwork for identifying the extent of inventory discrepancies.

- Investing in an IMS is one of the fastest ways to improve accuracy and minimize losses.

- Warehouse crews move pallets from receiving to their warehousing space quickly to make room for the next shipment.

- Of course, the obvious downside is that customers may look elsewhere.

- So what can ecommerce business owners do to prevent shrinkage?

However, the scope of reducing the temperament of carelessness can turn the wheel around to reduce Inventory shrinkage. There are a lot of ways in which a business can save the cost of inventory shrinkage. Simply curate the right tricks and rules and implement some in the business. It is vital to understand the major causes of inventory shrinkage to reduce the inventory shrinkage rate. It is also vital to curate measures to rectify the causes of shrinkage. If you can’t find where else shrinkage may be occurring, it’s worth looking at your management system.

Best Practices: Monitor the Right Inventory Metrics

One of the most effective tools for real-time tracking is Warehouse 15 by Cleverence. The best inventory software for small businesses is the one you’ll actually use. Look for tools that match your size, sales model, and growth plans.

What is the Difference Between Inventory Shrinkage and Inventory Loss?

It encompasses issues like theft, spoilage, administrative errors, and more. The cost can be staggering, both in terms of direct financial losses and the erosion of customer trust. However, with the right strategic approach, businesses can significantly reduce this risk. Put simply, inventory shrinkage refers to the loss, theft, miscounting, or damage of goods in the warehouse. Though shrinkage is most commonly the result of lost and damaged goods or outright employee theft, it can also be the result of incorrect outgoing inventory. Shrinkage, which includes inventory losses due to theft, administrative errors, or supplier discrepancies, directly affects the bottom line of retail pharmacies.

Employees pocket cash payments without ever adding the transaction to the system. Whether your staff is committing petty theft or skimming fraud, all forms of employee theft will adversely affect your bottom line. Another great way to reduce inventory loss is using tablet and mobile holsters.

Maximize Your ERP Accounting Software: 5 Tips to Find the Best VAR

And it’s not just big businesses that are affected by shrinkage; small businesses experience losses, too – often with less of a profit and operational cushion to absorb. That doesn’t necessarily mean that it’s missing; it’s just that a business can’t sell it to a customer. For example, shrinkage is a big issue in the restaurant industry, where they almost exclusively use perishable goods. It decreases the cost per unit, in turn lowering the cost of goods sold (COGS). Inventory shrinking effectively increases the cost per unit, which in turn increases the COGS.

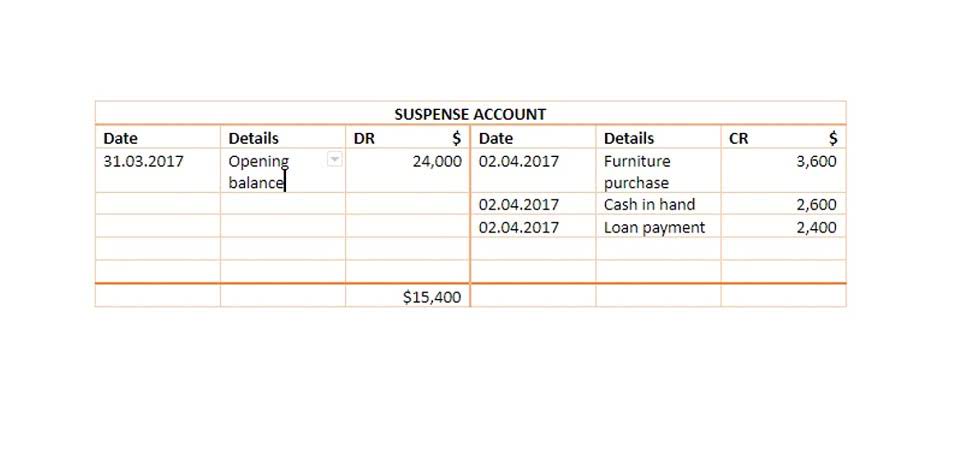

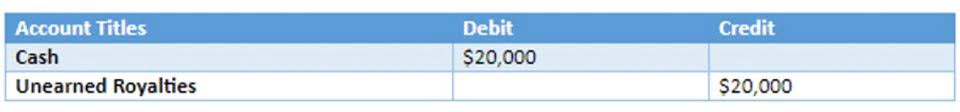

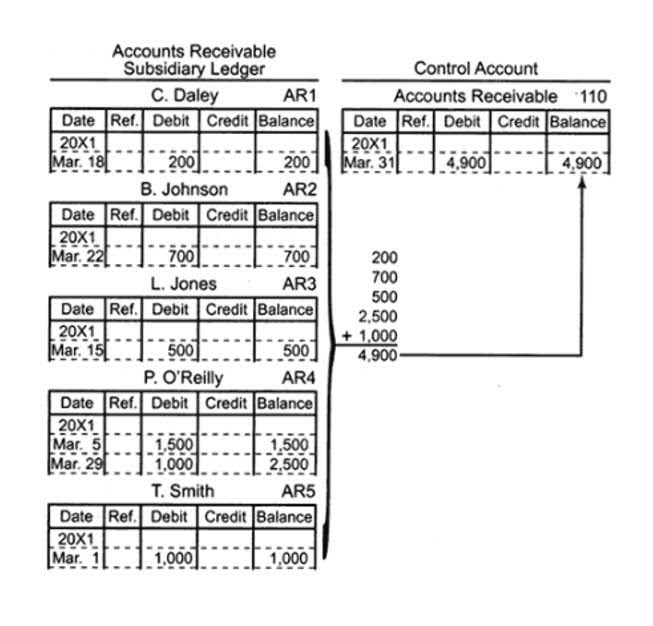

If the loss occurred is small, debit it in the cost of goods sold account (COGS). If the loss occurred is large, it will need a specific account. Create a new account that especially accommodates the losses that occurred due to shrinkage. This way, you will be able to manage your gross profit excluding the mass loss. Even the best policies are of no help if employees don’t understand them.

Statistics say employee theft holds 42% of the inventory shrinkage of the company or the business. The reason is, the employees are in the closest proximity of the inventory, and can find loopholes in the security (in the warehouses/stores). When you want to see its impact on your business, you’ll need to know how to calculate inventory shrinkage. This strategy is one of many vital inventory management 3 Ways To Reduce Inventory Shrinkage techniques.

Leveraging forecasting software such as StockTrim helps anticipate demand accurately, minimizing over‑stocking and shrinkage. Calculating the percentage of inventory shrinkage is a bit more complicated. Instead of calculating the percentage of units missing from the whole, you’ll calculate the total value missing. This gives a more accurate picture of how much inventory shrinkage costs a business. Inventory shrinkage is an umbrella term that businesses use to refer to inventory losses that were not part of sales.